Environment/EMC/EMI

Carnegie Mellon University

18-849b Dependable Embedded Systems

Spring 1999

Author: Eushiuan Tran

Abstract:

Embedded systems can exist in environments that are very harsh and noisy, which

can lead to potential problems with electromagnetic interference (EMI). EMI

consists of any unwanted, spurious, conducted, or radiated signals of

electrical origin that can cause degradation in equipment performance. Because

of these problems, all components must comply with specifications to ensure

electromagnetic compatibility (EMC), and there are numerous design methods that

can be used to prevent EMI. During the development life cycle of an embedded

system, the product must be designed to comply with EMC standards, and the

product must also be tested for EMC. In addition, other forms of environmental

reliability testing must also be performed to ensure dependable system

performance in its natural environment. Currently, there is still work to be

done to harmonize various EMC standards to reduce trade barriers between

countries and different use sectors, like Defense and Civilian. Therefore, care

must be taken in developing embedded systems for compliance with the

appropriate standards.

Contents:

Introduction

Embedded systems exist in a wide variety of environments. Because of this,

special care must be taken in developing embedded systems that they can operate

functionally in their intended environment. Many embedded systems exist in very

harsh and noisy environments, which can lead to potential problems with

electromagnetic interference (EMI). EMI consists of any unwanted, spurious,

conducted, or radiated signals of electrical origin that can cause unacceptable

degradation in system or equipment performance. Electromagnetic compatibility

(EMC) is the ability of systems to function as designed, without malfunction or

unacceptable degradation of performance due to EMI withing their operational

environment. Any electrical, electromechanical, or electronic equipment must

not adversely affect the performance of any other equipment or system as a

result of EMI and vice versa. Examples of EMC problems include a computer

interfering with FM radio reception, an operating vacuum cleaner causing

"snow" on TV, a car radio buzzing when you drive under a power line,

an airport radar interfering with laptop computer display, and a telephone

being damaged by lightning-induced surges on phone line. [emclab99] While the

effects of EMI are sometimes minor, like momentary interference on television,

other times the effect may be more catastrophic. For example, a serious

consequence can occur if a signal interferes with the operation of a medical

equipment that was being used to monitor a patient in intensive care. The

origins of EMI are electrical, with the unwanted emissions being either

conducted (voltages or currents) or radiated (electric or magnetic fields). For

EMI to occur, 3 essential elements must exist: an electrical noise (EMI)

source, a coupling path, and a victim receptor. The coupling path from a source

to a receptor can be in 1 of 4 categories: conducted (electric current),

inductively coupled (magnetic field), capacitively coupled (electric field),

and radiated (electromagnetic field). [emclab99] More details will be given

below about the sources and receptors. EMI can occur in 2 different situations:

intersystem EMI and intrasystem EMI. Intersystem EMI occurs between 2 or more

discrete systems while intrasystem EMI occurs between elements in the same

system. [Violette87]

Key Concepts

Sources of EMI An EMI

source can be any device that transmits, distributes, processes, or utilizes

any form of electrical energy where some aspect of its operation generates

conducted or radiated signals that can cause equipment performance degradation.

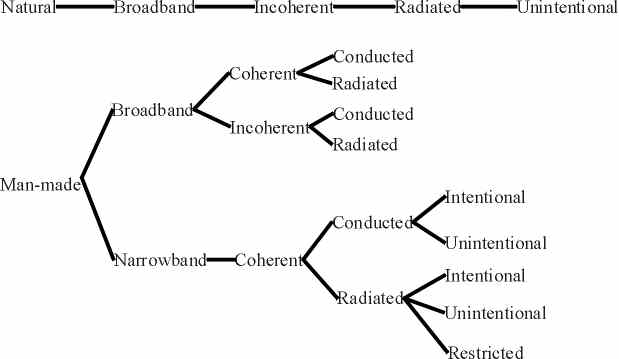

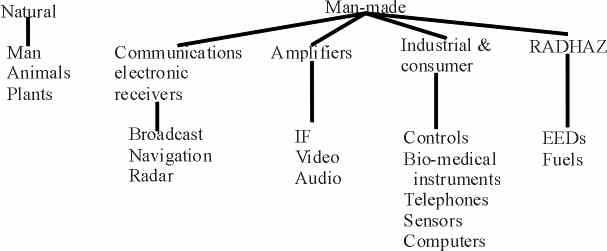

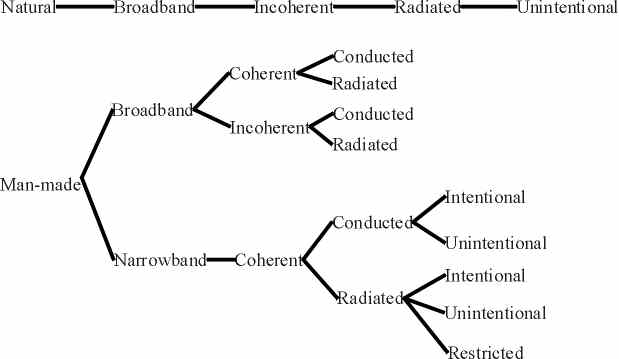

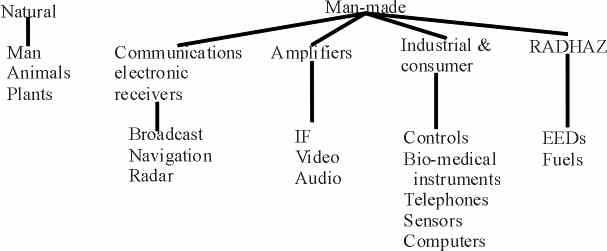

Figure 1 shows a taxonomy of the different sources of electromagnetic

interference. A brief description of each category will be given below.

[Violette87]

Figure 1: Taxonomy of EMI Sources [Violette87]

- Natural EMI sources - Sources that are associated with natural

phenomena. They include atmospheric charge/discharge phenomena such as

lightening and preciptitation static, and extraterrestrial souces including

radiation from the sum and galactic sources such as radio stars, galaxies, and

other cosmic sources. As shown in the above diagram, all natural sources are

classified as broadband, incoherent, radiated, and unintentional.

- Man-made EMI sources - Sources associated with man-made devices

such as power lines, auto ignition, fluorescent lights, etc.

- Broadband EMI - Electromagnetic conducted and radiated signals

whose amplitude variation as a function of frequency extends over a frequency

range greater than the bandwidth of the receptor.

- Narrowband EMI - Electromagnetic conducted and radiated signals

whose amplitude variation as a function of frequency extends over a frequency

range narrower than the bandwidth of the receptor.

- Coherent broadband signals - Neighboring components of the signal

(in the frequency domain) has a well-defined amplitude, frequency, and phase

relationship.

- Incoherent broadband signals - Neighboring components of the signal

(in the frequency domain) are random or pseudo-random (bandwidth limited) in

phase or amplitude.

- Conducted EMI - Noise signals transmitted via electrical conduction

paths (i.e. wires, ground planes, etc.).

- Radiated EMI - Electric and magnetic fields transmitted through

space from source to receptor.

- Intentional radiating emitters - Emitters whose primary function

depends on radiated emitters. Examples include electronic licensed

communication systems. These include communication, navigation, and radar

systems.

- Unintentional (incidential) radiating devices - Devices that

radiate radio frequencies but is not considered their primary function.

- Restricted radiating devices - Devices that intentionally use

electromagnetic radiation for purposes other than communication or data

transfer. (i.e. garage door operating systems, wireless microphones, etc.)

[Violette87]

Receptors of EMI Any

EMI situation requires not only an emission source but also a receptor. A

receptor is also called a "victim" source because it consists of any

device, when exposed to conducted or radiated electromagnetic energy from

emitting sources, will degrade or malfunction in performance. Many devices can

be emission sources and receptors simultaneously. For example, most

communication electronic systems can be emission and receptor sources because

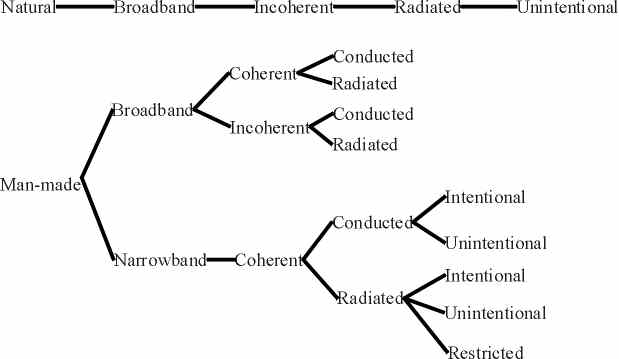

they contain transmitters and receivers. Figure 2 shows a taxonomy of different

receptors that are susceptible to EMI. Similar to the emission source taxonomy,

receptors can be divided into natural and man-made receptors. A brief

description of each category will be given below. [Violette87]

Figure 2: Taxonomy of EMI receptors [Violette87]

- Natural EMI receptors - Natural receptors include humans, animals,

and plants.

- Man-made EMI receptors - Man-made receptors can be categorized into

4 categories: communication electronic receivers, amplifiers, industrial and

comsumer devices, and RADHAZ.

- Communication electronic receivers - These receivers include

broadcast receivers, communication receivers, relay communication receivers,

and radar receivers.

- Amplifiers - Amplifiers include IF, video, and audio amplifiers.

- Industrial and consumer receptors - Industrial receptors include

digital computers, industrial process controls, electronic test equipments,

biomedical instruments, and public address systems and intercoms. Consumer

receptors include radio and TV receivers, hi-fi stereo equipment, electronic

musical instruments, and climate control systems.

- RADHAZ - This category includes radiation hazards to

electro-explosive devices and fuels. RADHAZ is an acronym for RADiation

HAZards, the name given by the U. S. Department of Defense to the program that

is determining the extent of radiation hazards and methods for controlling

them. [Violette87]

EMC Design Considerations

During the design process, engineers must be certain that the system is

designed to comply to EMC standards. There are many design considerations that

need to be taken into account. While it is not the point of this paper to give

detail explanations about EMC design techniques, brief descriptions will be

given simply for an overview. Engineers needing more technical details can

refer to any EMC handbook.

Cable wiring and harnessing is a significant EMI concern. Cables are

required to distribute electrical power and transmit electrical signals for the

operation of various systems. Since cables are usually routed to accomodate its

function, it is often difficult to quantify its environment and it usually

varies over both frequency and electric and magnetic field amplitudes. Cables

can be EMI radiating sources if they act as radiating antennas, or be

susceptible to EMI if they are receiving antennas. Cables can also be coupling

paths. In addition, cables are sometimes harnessed together, so interference

can also be between two cables that are close in proximity. Therefore, their

performance is very difficult to predict. Many specifications classify wiring

or cable types into four to six categories but these classifications are

generally qualitative in nature. More quantitative classifications should look

at levels of power transmitted, or susceptibility of termination. [Violette87]

Connectors are contacts that either link or separate two cables or other

equipments. There may be anywhere from several to hundreds of individual

wire-pins or coaxial sheaths making simultaneous cotact via a connector. EMI

problems from connectors are usually related to poor contact which may result

in arcing, or overheating that leads to arcing. Poor contact connections can

also result in driven-circuit voltage variations from the contact impedence

modulation of the driving-circuit source. Impedence coupling from outside

sources can happen in connector grounding paths. Improperly shielded connectors

or poor cable-connector-equipment- enclosure contact can cause radiated

emission penetration or leaking through apertures. [Violette87]

Grounding is one of the least understood EMC subjects, despite the fact that

it seems straightforward. Improper grounding is the source of many EMI

problems. Grounding is necessary to prevent shock hazard, which occurs when a

wiring or component insulation in an equipement frame or housing breaks down.

Grounding also protects against lightning damage. Grounding is also necessary

to reduce EMI due to electric field flux coupling, magnetic field flux

coupling, and common impedance coupling. There are two reasons why grounding is

not understood well. One reason is that shock and safety control requirements

existed before the electronics and high frequency area, so traditional

grounding techniques were developed to satisfy those requirements. A second

reason is that sometimes a conflict occurs between requirements for safety

grounds and EMI control. [Violette87]

Different considerations must be taken into account with shielding.

Shielding is the use of conductive materials to reduce radiated EMI reflection

or absorption. Usually, the theoretical attenuation offered by materials to

electric, magnetic, and electromagnetic waves does not match that achieved in

practice. This is because a shielded enclosure or housing is not completely

sealed. Any shielding application has some kind of penetrations and apertures

like meter windows, cover plates and access cover members, and push buttons.

These apertures cause leakage and therefore compromises the integrity of the

shielding material. Shielding integrity can be restored through the use of EMC

gaskets, EMC sealants, and conductive grease. Gaskets provide either temporary

or semipermanent sealing applications between joints and structures. Sealants

include conductive epoxies which are used to join, bond, and seal two or more

metallic metaling surfaces, and conductive caulking which is used to shield and

seal two or more metallic mating members held together by other mechanical

means. Conductive grease provides a low-resistivity contact path between mating

members. [Violette87]

The previous design considerations dealt with topics that represent problems

between sources and receptors. There are also EMI control techniques that are

applied at the component, circuit, and equipment levels. The problem with

resistors, inductors, and capacitors is that they do not behave at their stated

values, especially at high frequencies due to the effects of parasitic

inductance and capacitance. Under certain conditions, their performace degrades

at frequencies as low as 1MHz. Inductive devices like transformers, solenoids,

and relays produce low-impedence fields that are sources of EMI if they are

uncontrolled. The main techniques available for controlling transient-producing

devices involves using diodes and filters, and for controlling magnetic fields

involves shielding. Surface tracking is an insulator problem that is a source

of EMI. Surface tracking (or leakage) is a condition in which small currents

creep across the insulator. It is caused by surface contamination of the

insulation by moisture or solid conductive particles. The EMI control technique

is to protect from contamination through the use of proper material and proper

voltage design. Techniques used to minimize EMI in conductors include coating

conductors with a high-permeability material and using hollow conductors at

higher frequencies to minimize external fields. There are many techniques for

different components, not all of which are listed here. This section only

serves as a brief introduction. [Violette87]

Radio-frequency interference (RFI) is a serious EMI problem today due

largely to the large number of radio transmitters that exist. Radio

transmitters range from large, high-power transmitters such as broadcast,

communications, and radar to small, low-power equipments such as handheld

radios and cellular telephones. The problem with radio transmitters is twofold,

as equipment can cause interference to nearby radio and television receivers,

and equipment can be upset by nearby transmitters. Radio and television

receivers can be very vulnerable to RFI pollution from nearby computers.

Repetitive digital signals contain harmonics that can extend into the GHz

range. This unwanted energy can be radiated through cables and wiring acting as

antennas, or conducted through the ac power system. If the levels are high

enough, the receivers can be damaged. It was this emissions problem that caused

countries around the world to pass EMI regulations. In the U.S., complaints

from consumers about interference with television disruption in the 70's drove

the FCC to initiate mandatory EMI testing of personal and commercial computers

in the 1980's. Digital circuits are usually the primary source of emissions,

and analog circuits are more vulnerable to RFI than digital circuits. In

protecting equipment against RFI, it is important to start at the circuit

level. Filters can be used and sometimes multistage filters are needed. Slots

and seams cause the most problem in RFI shielding, so high-quality shields and

connectors are needed for adequate RFI protection. [Gerke94]

Electrostatic discharge (ESD) is also an EMI problem. An ESD event starts

with a very slow buildup of energy, followed by a very rapid breakdown. It is

this fast breakdown that causes EMI problems in modern electronic systems. The

energy discharge yields EMI frequencies in the hundreds of megahertz. The high

speed and frequency of the ESD energy can damage circuits, bounce grounds, and

cause upsets through electromagnetic coupling. The most common method of ESD

generation is triboelectric charging which is caused by stripping electrons

from one object and depositing electrons on another object. In an insulator, it

may be a long time before charge recombination occurs, so a voltage builds. If

the voltage becomes large enough, a rapid breakdown occurs in the air, creating

the ESD arc or spark. Sources of triboelectric charging includes humans,

furniture, and material or device movement. Humidity also affects ESD as the

lower the humidity, the higher the likelihood of ESD problems. High humidity is

helpful because the moisture reduces surface impedance and allows charges to

recombine at a faster rate. However, high humidity leads leads to surface

tracking or leakage at lower temperatures, so there is a tradeoff. ESD has

several failure modes that are not completely independent of one another. These

include direct hit to circuit, ground bounce, electromagnetic field coupling,

and predischarge electric field. Like RFI problems, good protection against ESD

problems start at the circuit level through the use of filters and multilayer

boards. High-quality shields and connectors can be used for good ESD cable

protection. The length-to-width ratio for grounds should be less than 3 to 1.

Thin materials are adequate for shielding and special attention must be paid to

slots and penetrations. [Gerke94]

In addition to the design considerations above, there are other EMC issues

in the design of embedded systems. One is the compatibility among transmitters

that are designed to work together. For example, when every car has a

forward-pointing smart cruise control radar, and they are either next to each

other or coming head-on at each other, the transmitters must be designed that

there is not interference. Another problem to consider is what happens when a

component is inserted in an intergrated system and causes EMI. For example,

computer motherboards are designed with empty slots for different cards to be

plugged into. In particular, video cards are FCC certified to ensure that they

are compatible with whichever motherboard they are plugged into.

There are also issues concerning EMC when humans are the receptors. A scare

that has not yet been proven deals with cellular phone emissions. A source

cited that radiation emitted from cellular phones has shown to cause short-term

memory loss and lapses in concentration. However, this is not a proven fact

yet. There was also an early brain cancer scare with cell phones that actually

led to the FCC limiting the transmitting power of handheld cell phones to 0.3

watts.

Environmental Reliability

Testing

Environmental reliability testing is a systematic approach to the

collection, analysis, and application of information regarding service use in

environmental conditions. Environmental measurement and test became a growing

concern during World War II and the Korean War and a discipline by the Space

Race and the Vietnam War. It is very important that we understand the

interactions of manufactured products and the environmental stresses they

encounter when in use. Environmental reliability testing can be divided into

three categories: development testing, verification testing, and production

testing. Development testing refers to all tests performed generally before the

design goes into production. Verification testing refers to testing performed

on the production configuration. Production testing refers to the application

of environmental stresses to large product populations to improve the

manufacturing process and to verify that it remains under control. Questions to

take into consideration for each type of testing are listed below. [Caruso96]

- How will the product respond structurally, thermally, and in other ways to

environmental stresses?

- What are the strength limits of the product?

- Which materials and manufacturing processes are best suited to the

product?

- Which test setups, fixtures, and stress application methodologies are best

suited to the sought after product information?

- How close do the performance and reliability characteristics of the

product come to design predictions and customer expectations?

- What is the correlation of long-term test results to service life?

- How can the accumulation of fatigue stress be reliabily accelerated

through test compression and exaggeration?

- Which environmental test techniques are best suited to revealing the type

of processing flaws most likely to be present in the product?

- What percentage of the product population should be evaluated to provide

confidence in the robustness of the production process?

- What is the appropriate level of assembly at which to apply environmental

stresses to maximize the likelihood of defect disclosure at the least cost?

- What is the best way to assure integrity of vendor-supplied elements of

the product?

A brief description of the various testing techniques will be presented

below.

- Product characterization - To determine through stress response

surveys how the product will respond structurally, thermally, and in other

relevant ways to environmental stresses.

- Accelerated life tests - Tests that involves applying environmental

stress levels and other conditions that are exaggerated beyond normal service

levels. An example of one test is step-stress or fragility testing where

progressively higher stress levels are applied until the product fails.

- Materials and methodology evaluations - It is important to run

controlled experiments to compare the relative effectiveness of different

materials and assembly processes.

- Test, analyze, and improve tests - Tests where the product is

tested until failure, fixed, and then tested some more. This is a kind of

iterative testing combined with progressive incorporation of test improvements.

- Fatigue/durability tests - Tests that evaluate a product's

long-term performance and survivability through repeated application of

significant environmental stresses for many test cycles. [Caruso96]

- STRIFE testing - a combination of system level stess and life

testing that involves operating conditions exceeding the recommended limits in

order to find weak components. [Siewiorek91]

- Environmental stress sceening - Process used to precipitate

manufacturing defects and infant mortality failures prior to delivery. It uses

increased environmental stresses (i.e. temperature cycling, random vibration,

high temperature) to reveal design defects and process-induced defects.

It is important to note that most product verification tests are usually

one-time tests peformed on a representative sample of the product. Some tests

may degrade the equipment so it is unrealistic to run the test on every single

unit. This raises the issue whether running tests on a representative sample of

the product is a reliable prediction that all of the units will pass the test.

Since you cannot run the test on every single unit, how many units should the

test be performed on to get a good guarantee that all units will pass the test?

Another issue is what kind or levels of design changes requires re-verification

and re-certification? This is always a difficult issue to deal with, but it is

certainly a very realistic concern. There are different points to remember

when choosing environmental reliability tests for the development of any

embedded system. First, there is no universal test procedure. No test will be

completely effective in all environmental situations and each test has its

strengths and weaknesses. The cheapest test is not always the best test as

short-term and long-term tests are optimized for different purposes. There is

no universal test purpose as each test has different goals. Test results are

relative, not absolute. Therefore, test expectations should be realistic.

Lessons from past experiences are also relevant, even if the testing techniques

are obsolete. The purpose and goal of a test should be defined before the test

is performed. Finally, no test can satisfy the goals of the overall testing

process. Tests should be carefully chosen to eliminate nonproductive efforts,

minimize redundancy, and maximize the likelihood of obtaining useful

information. [Caruso96]

Standards Compliance

The ability to sell electronic products depends upon the products being able

to meet the specifications contained in various regulations. Therefore, a brief

study of the different emission standards is necessary. In the United States,

the Federal Communications Commission (FCC) Rules and Regulations, Part 15

Subpart J deals with unintentional emissions from equipment that use digital

techniques and generate or use timing signals or pulses of frequencies in

excess of 10kHZ, or has a pulse rate of 10,000 pulses per second or higher.

These specifications were first formed when users of television and other radio

receivers complained about the interference of radiation from nearby operating

digital devices. FCC 15J defines 2 classes of computing devices that must

conform to emissions specifications. Computing devices refer to any computer

peripheral including modems, printers, and other I/O devices. The 2 classes are

defined as follows:

- Class A: "A computing device that is marketed for use in a

commercial, industrial, or business environment; exclusive of a device which is

marketed for use by the general public, or which is intended to be used in the

home."

Class B: "A computing device that is marketed for use in a

residential environment notwithstanding use in commercial, business, and

environmental environments."

A device that passes Class B limits may be used in a Class A environment. There

are different tests that are required for FCC compliance. There are 3 different

types of FCC compliance as stated in the FCC Rules and Regulations.

- Type approval - Based on equipment examination and test by the FCC.

- Type acceptance - Based on representation and test data for

equipment to be used pursuant to a station authorization. Testing is performed

by the manufacturer and the data is not required unless specifically requested

by the FCC.

- Certification - Based on representation and test data for equipment

designed to be operated without individual license under Rules and Regulations

Parts 15 and 18. Testing is performed by the manufacturer and the test data is

required by the FCC. [Violette87]

The International Special Committee on Radio Frequency Interference (CISPR) is

an organization sponsored by the International Electrotechnical Commission

(IEC). CISPR is composed of each of the national committees of the IEC, a

United Nations commission, and other international unions, commissions, and

committees. It is responsible for setting uniform limits on electromagnetic

emissions from equipment so that trade would not be inhibited between member

countries as a result of different emissions specifications. CISPR publications

deal with inteference for the following items:

- Microwave ovens with power consumption below 5 kW

- Ignition systems

- Televisions, FM receivers, and AM receiver power-line susceptibility

- Conducted and radiated emission of household appliances, portable tools up

to 2 kW, office machines, dimmer regulators, and other electrical apparatus

- Fluorescent lamps

Compliance with CISPR usually varies from country to country and each country

has their own regulations regarding enforcement of the limits. [Violette87]

Currently, there is worldwide effort towards harmonizing various EMC

standards to reduce the trade barriers between countries and various sectors

like Defense and Civilian. The lack of harmonization of standards is a great

burden on manufacturers of electrical and electronic systems because it

increases the duration of the product development cycle and the compliance

evaluation costs. The increased use of these products has made it absolutely

necessary to harmonize various EMC standards. In the Defense sector, the

success of military missions is dependent on the trouble-free field performance

of the electronic and communication equipments used. In the Civilian sector, it

is necessary to protect the radio frequency spectrum from the electromagnetic

noise emission of electrical systems. CISPR has provided recommendations for

the implementation of EMC. However, each country can choose its own set of test

instrumentation, test procedures, and test limits in their own EMC standards.

This causes any manufacturer wishing to supply electronic equipments to

different countries and the Defense and Civilian sector having to deal with a

plethora of EMC standards. [Sampath97]

In Europe, the market unification of 16 countries to form the European Union

has affected the EMC standards scenario. The national EMC standards of these

countries are being combined to form a harmonized EMC standard, called European

Norms. This became known as the EMC Directive which went into effect January 1,

1996. All products that complied to the EMC Directive would bear a CE marking.

This mark was required for any nation that wanted to sell electrical equipment

in the European Community. Compliance can be completed by the following three

ways:

- Self-certification by manufacturer - The manufacturer performs the

tests using in-house test equipment or a commercial test house. After the tests

are completed and documented, the manufacturer files for a declaration of

compliance.

- Technical Construction File (TCF) - The manufacturer prepares a TCF

which decribes the product, sets out the procedures used to ensure conformity

of the product, and includes a technical report or certificate from a Competent

Body which are test facilities designated by member states as able to make

decisions regarding compliance with the EMC Directive. Once the TCF is

completed, the manufacturer files for declaration of compliance.

- Type acceptance - An EC type examination certificate issued by one

of the Notified Bodies is required. Notified Bodies are usually government

agencies in member states.

In the United States, the MIL-STD-461D issued by the Department of Defense

represents a harmonized standard for military equipments and subsystems.

Even with all the work that has been done to harmonize EMC standards, there

are still more than 20 European Norms on EMC, various MIL-STD-461 documents,

different FCC Rules and Regulations parts, and other EMC specifications from

different industries. This still results in problems including different test

requirements and different limits and units of measurements. Currently, 5

certification bodies in the world, North America's Underwriters Laboratories

(UL), Germany's VDE, Italy's IMQ, the UK's BABT, and the TUV Product Services

have teamed up to issue an international EMC mark to products that meet all of

the standards followed by the major economies. Even though acquiring this

international mark requires product testing to comply to each standard and a

high bill toward testing charges, it is a good step toward achieving a global

EMC compliance certificate for a product. [Sampath97]

Available tools, techniques, and metrics

EMI testing is needed because EMI predictions and analysis alone are inadequate

to assure compliance with EMI regulations. It is also necessary due to the

complexity of design for EMC. There are a number of methods and nomenclature

used in measuring EMI emission and susceptibility characteristics of equipment

and subsystems. There are three levels of testings that exist and generally,

the higher the level of testing, the more difficult and expensive it becomes.

- Low-level testing - Component, equipment, and subsystem testing.

Basically, low-level testing ensures that there will be very few EMI problems

when testing at the next higher level.

- Intermediate-level testing - System and vehicle testing. This

involves testing for EMI degradation or malfunction due to self-jamming.

- High-level testing - Electromagnetic environment (EME) interaction

with the test item. Even after low-level and intermediate level testing,

numerous problems can occur when the product is operating in its natural

environment. [Violette87]

EMI testing can also be divided into three categories - compliance,

engineering, and audit testing.

- Compliance tests - These tests are run to prove that the design

meets appropriate EMI requirements. These tests require very precise and

absolute measurements, so expensive equipment and experienced personnel is

needed. Compliance testing is performed at the end of the design but before

sale of the product. Testing can be performed either using an independent EMI

test laboratory or an in-house EMI test laboratory.

- Engineering tests - The objective of these tests is to uncover

potential problems early in the design process. This is when you have the most

time and flexibility in making design changes. Unlike compliance testing,

engineering testing does not require high precision and accuracy to obtain good

results, so simple tests with inexpensive equipment is satisfactory. EMI

engineering tests are performed in-house. Some tests include emission

prescreening, ESD prescreening, RFI prescreening, and power-disturbance

prescreening.

- Audit tests - Audit tests are associated with manufacturing and

quality, not with design. The goal of audit testing is to ensure that the

design stays intact through its product life. An example of audit testing is

statistical checks, where a unit is occasionally pulled off the production line

and run through a series of EMI tests. Screening tests on all production units

can prevent faulty units from leaving the production plant but it can be very

expensive. [Gerke94]

Relationship to other topics

Conclusions

There are several important conclusions to take away from this section. Mainly,

they are the following:

- EMI is a major problem in the development of embedded systems. Since

embedded systems often exists in very noisy environments, even more attention

must be paid to EMC.

- EMC must be taken into consideration during the design stage. Designing

for EMC is a long process that starts early in the life cycle and proceeds

through the testing stage and even in the post-production stage. Therefore, EMC

is a concern for engineers at all phases of the developement of an embedded

system.

- Environmental reliability testing is used to eliminate potential problems

that the system can experience when it is operating in its natural environment.

- There are many EMC standards used in the regulation of products that may

cause EMI.

EMC is a very important issue that embedded systems designers have to deal

with. Even though it is a very difficult topic, there are may practical design

techniques that can be used to design for EMC. This will greatly assist

designers who are unfamiliar with EM theory to be confident in their design for

EMC.

Annotated Reference List

- [Caruso96] Caruso, Hank, "An Overview of Environmental Reliability

Engineering," Proceedings of Annual Reliability and Maintainability

Symposium, Las Vegas, NV, 1996, pp. 102-109.

This paper presents an overview of different testing techniques used in

environmental reliability engineering.

- [Gerke94] Gerke, Daryl and Kimmel, Bill, "ESD as an EMI problem ...

how to prevent and fix," EDN's Designer's Guide to Electromagnetic

Compatibility, vol. 39, no. 2, January 20, 1994, pp. 23-32.

This paper gives an overview of what is ESD, the EMI problems related to ESD,

and how to prevent these problems.

- [Gerke94] Gerke, Daryl and Kimmel, Bill, "Radio-frequency

interference ... why computers and radios hate each other," EDN's

Designer's Guide to Electromagnetic Compatibility, vol. 39, no. 2, January

20, 1994, pp. 33-40.

This paper gives an overwiew of what is RFI, the EMI problems related to RFI,

and how to prevent these problems.

- [Gerke94] Gerke, Daryl and Kimmel, Bill, "EMI testing ... if you wait

until the end, it's too late," EDN's Designer's Guide to

Electromagnetic Compatibility, vol. 39, no. 2, January 20, 1994, pp.

101-108.

This paper describes the different categories of EMI testing which are

compliance testing, engineering testing, and audit testing.

- [Sampath97] Sampath, K., Subramanian, C., and Das, Sisir K.,

"Harmonization of International EMC Standards," Proceedings of the

International Conference on Electromagnetic Interference and Compatibility,

Chennai, India, 1997, pp. 127-132.

This paper discusses the EMC regulation harmonization efforts performed by

different countries.

- [Siewiorek91] Siewiorek, Daniel P. and Koopman Jr., Philip John, The

Architecture of Supercomputers - Titan, A Case Study, San Diego, CA: Academic

Press, Inc., 1991.

Contains explanation of STRIFE testing.

- [Violette87] Violette, J. L. Norman, White, Donald R. J., and Violette,

Michael F., Electromagnetic Compatibility Handbook, New York: Van

Nostrand Reinhold Company, 1987.

This is an EMC handbook intended for engineers and technicians working with

electrical and electronic equipment.

- [emclab99] http://www.emclab.umr.edu, University

of Missouri-Rolla Electromagnetic Compatibility Laboratory, accessed April

14, 1999.

This website contains general EMC-related information, information on EMC

modeling tools, and information about the work done at the EMC Laboratory at

the University of Missouri-Rolla.

Further Reading

- Gerke, Daryl and Kimmel, Bill, EDN's Designer's Guide to

Electromagnetic Compatibility, vol. 39, no. 2, January 20, 1994.

A special supplement to EDN magazine. The audience of this supplement is

practicing engineers who need to understand about EMC but have little

background in the area. The focus is on practical insights and ideas about EMI

that will help the engineer to identify, solve, and prevent EMI problems in

their design.

Loose Ends

Go To Project

Page